Overview

Trima Accel

Automated Blood Collection System

Reveos

Automated Blood Processing System

Welders & Sealers

Reliable, sterile connections using cost-effective tubing welders and sealers

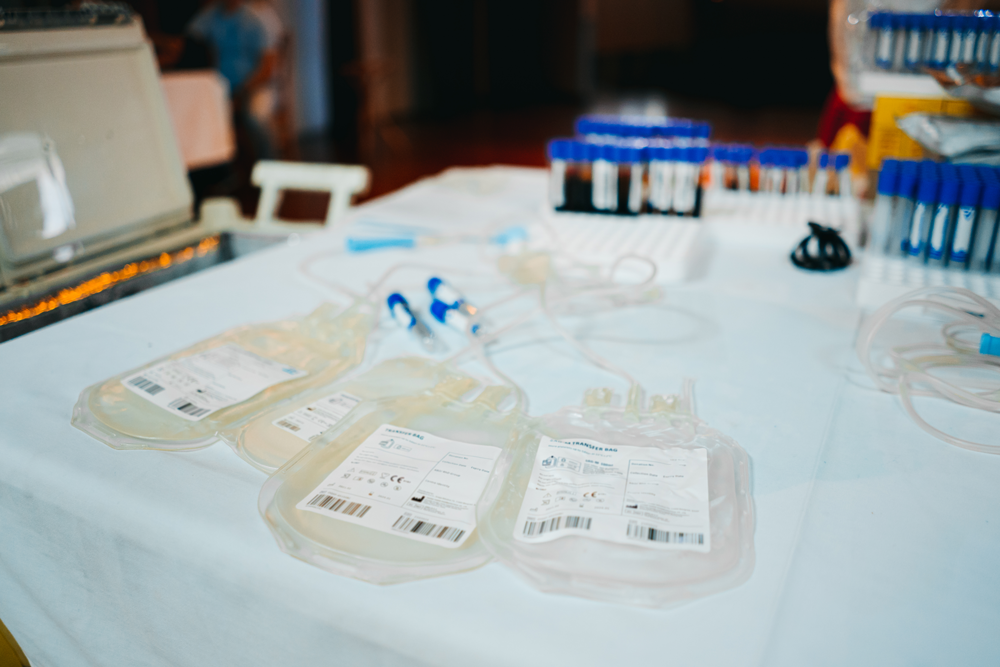

Whole Blood Bag Systems

Whole blood collection, component processing and storage

Mirasol

Pathogen Reduction Technology (PRT) System

See all

Overview

Spectra Optia

Apheresis System

Red Blood Cell Exchange

Therapeutic Apheresis Red Blood Cell Exchange

Therapeutic Plasma Exchange (TPE)

Exchange protocols available on the Spectra Optia Apheresis System

Therapeutic Plasma Exchange (TPE)

Exchange protocols available on the Spectra Optia Apheresis System

Therapeutic Plasma Exchange (TPE)

Exchange protocols available on the Spectra Optia Apheresis System

Therapeutic Plasma Exchange (TPE)

Exchange protocols available on the Spectra Optia Apheresis System

Therapeutic Plasma Exchange (TPE)

Exchange protocols available on the Spectra Optia Apheresis System

Cell Collections

Comprehensive cell collection solutions

Vascular Access

Your resource for optimizing vascular access for each and every patient

Sickle Cell Disease

Transfusion Therapy for Sickle Cell Disease

See all